When Scott Wine talks with dealers and customers of Case, New Holland and other CNH brand products, he often comes away with two responses.

The first response the CEO hears is that the CNH brands deliver “great iron.” Often the next sentence is, “We wish that you could be great with technology.”

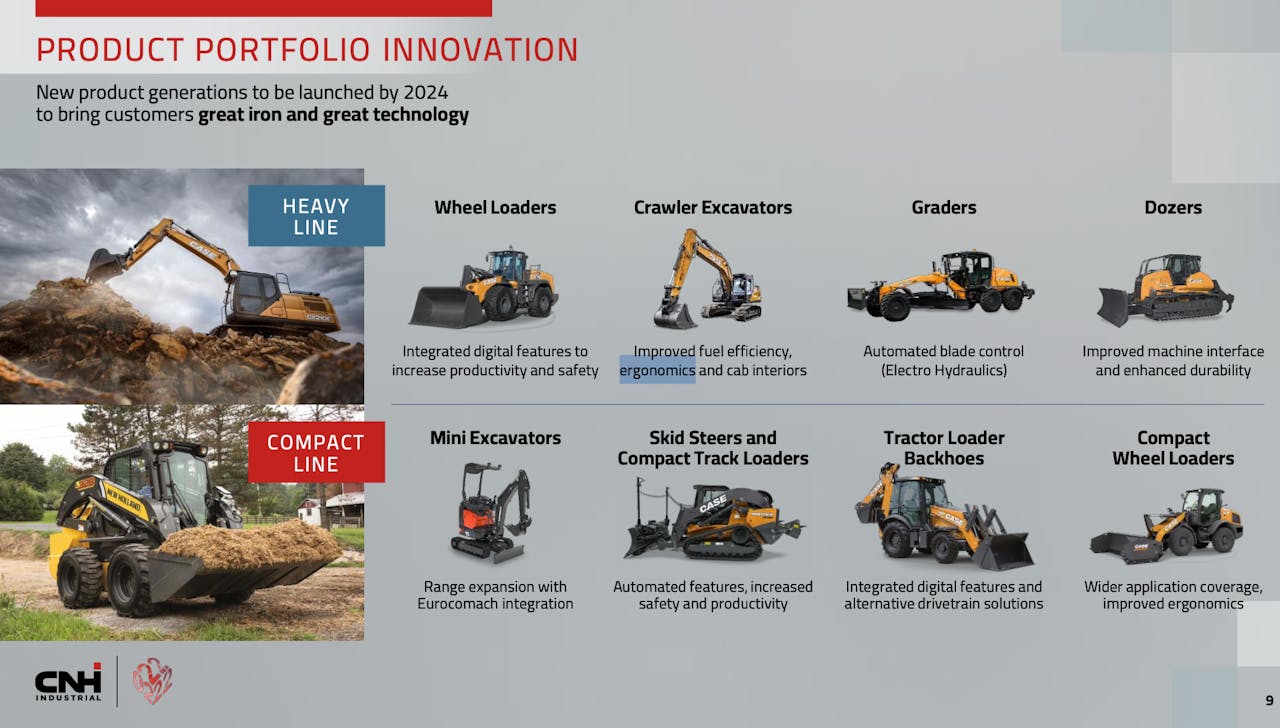

With that in mind, Wine and company leadership recently presented CNH’s Capital Market Day with the theme of “Breaking New Ground.” Part of breaking that new ground will involve the launch of more than 200 products over three years with a heavier focus on new technologies, such as automation and electrification.

“Think about the idea of breaking new ground; it’s what our equipment does, both on the construction and the ag side. But also innovation, sustainability and productivity are the things that will drive us going forward,” said Wine, chief executive officer of CNH Industrial. “This represents our North Star of what we will be and what we will follow on the way forward.”

With recent acquisitions and partnerships with Raven, Augmenta, Monarch and Trimble, Wine believes the company is on a path to achieving that greatness.

“What we’re going to talk about is this idea of marrying great iron with great technology,” he said. “It’s just so many different things that we can do with technology now with Raven at the core. What we believe is that by marrying that with much greater customer focus we could have a very bright future.”

Wine noted that brand and dealer strength is also significant. The focus is on the end-user customer and the dealer.

“That’s our goal, we’ve got a journey here to go on, whether it’s CRM capability, whether it’s parts support, whether it’s technology insertion, there is lots of work to do, but ultimately enhancing our brand in distribution. I like to say we can win in this game. If we’re great at product brand distribution, this is an easy game to win. It’s hard to do but our commitment is there.”

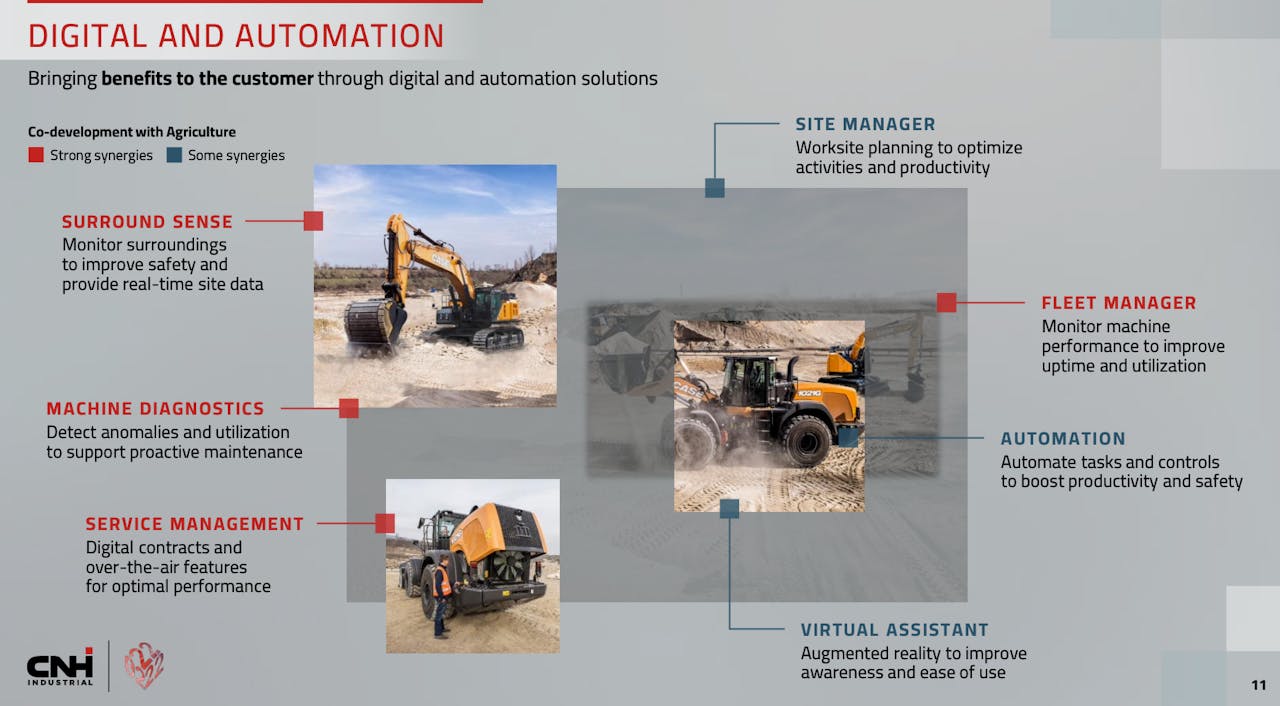

Core to the new CNH Industrial strategy is its focus on technology leadership in automation and its commitment to delivering a fully autonomous farming cycle, while increasingly extending this expertise to its construction segment.

“Every player in our industry along the supply chain is moving toward better more sustainable operations and products,” said Stefano Pampalone, CNH Industrial construction segement president. “These trends will shape a new construction equipment industry across the world, and we welcome the challenge.”

CNH Industrial

CNH Industrial

Digging in

CNH Industrial’s portfolio of construction equipment is sold under three brands, Case Construction Equipment, New Holland Construction and most recently Eurocomach, part of the portfolio acquired with Sampierana.

“Each has a strong heritage and position within its respective geography, serving customers with a tailored product offering,” he said. “Over the past two years we have taken a number of actions to position the construction segment for profitable growth.”

What they’ve found is that the more invested in ag, the more construction also sees benefits.

With that foundation in place, CNH Industrial is poised to accelerate the renewal of its construction segment offerings.

This started with the launch of new wheel loaders and the TV620B, the industry’s biggest compact track loader, both with advanced digital features and connectivity systems. The company’s overall portfolio of mini and midi excavators expanded through the acquisition of Sampierana.

Currently in the pipeline is the launch of the Minotaur, a blend of a large compact track loader and a dozer.

According to CNH, over the next three years nearly 200 products, approximately 150 in ag and over 50 In construction, will be brought to market.

Electric solutions for select models of compact excavators will be launched this year, followed by backhoe loaders, compact wheel loaders and compact track loaders in the years to come.

“We are designing our machines to elevate the operator’s experience and improve overall safety,” Pampalone said. “Digital and automation solutions aim to increase safety, productivity, uptime and profitability.”

Specifically, he cited machine control solutions and how they reduce operator fatigue by eliminating the need for joystick movements. For example, the person-detection system alerts operators to people or vehicles approaching.

Also, he said uptime is promoted through plan maintenance contracts, proactive dealer support with telematics alerts and other services such as oil sampling to detect and predict abnormal function. Fleet management enables better machine utilization by identifying and reducing idling time.

“Each of our customers has different requirements which are continuously evolving so we are enhancing a wider service and product offering with different price points and CNH levels of investments and full access for a wide variety of financial services through our CNH industrial capital,” Pampalone said.

CNH Industrial

CNH Industrial

Digital solutions

Pampalone said the product portfolio is central to reaching the company’s growth goals. By 2024 he said the company will have completed the renewal or upgrades of the totality of its heavy equipment lineup with digitization features and automation.

Launches of the next generation of small and medium-sized wheel loaders are expected in 2023. In addition, he said, next generation crawler excavators will be launched in Europe in March and in Q3 2022 in North America.

“Roadbuilding customers will benefit from new electric-hydraulic controls on graders and dozers enabling machine control automation capabilities,” Pampalone said. “For our compact line we firmly believe there is an electric future, and for each of the major product lines we are developing electric versions of selected models.

In addition, we are focusing on developing enhanced services and features that can be applicable throughout the range.”

The acquisition of Sampierana has brought in a competitive range of compact excavators built through a cost-effective supply chain, helping strengthening CNH’s presence in Europe.

“We are now fully committed to increasing the production capacity in order to integrate Sampierana into our existing mini and midi excavator offering, and we will quadruple Sampierana volumes by 2023,” he said. “Marrying technology leadership with our great iron will drive profitable growth.”

Data received from these new connected machines are used in many ways including in the design for future product features and digital services promoting uptime and productivity for customers through its dealer networks.

Examples include proactive alerts, predictive maintenance and remote support that are available today on some of the heavy equipment recently launched. “We are also in the process of scaling up these services, and we’ll be launching them on additional product lines later in 2022,” he said.

Also, enhancements on the 2D and 3D machine control and guidance solutions for added safety and productivity will be gradually rolled out across product lines over the next few years. Plans are in place for further integration of dealer systems with new digital tools.

“To enhance the customer experience, our goal is to digitize the entire workflow on the jobsite from the initial site survey all the way through to the final as-built map,” Pampalone said.

Overall, Wine sees the next few years as not fixing things from the bottom but building on a strong foundation.

“Most of the bold action will be for our customers because that’s what we’re striving to do,” he said. “We’re excited and expect you to see that we are playing to win. Trust that we will move with purpose and pace, our shoulders to the wheel, and I think you’re going to see why I’m so confident in the future.”