Remote control is an important step in what Cat calls the “road to autonomy.” Before your mind goes to the typical shoulder-harness remote-control console, think bigger.

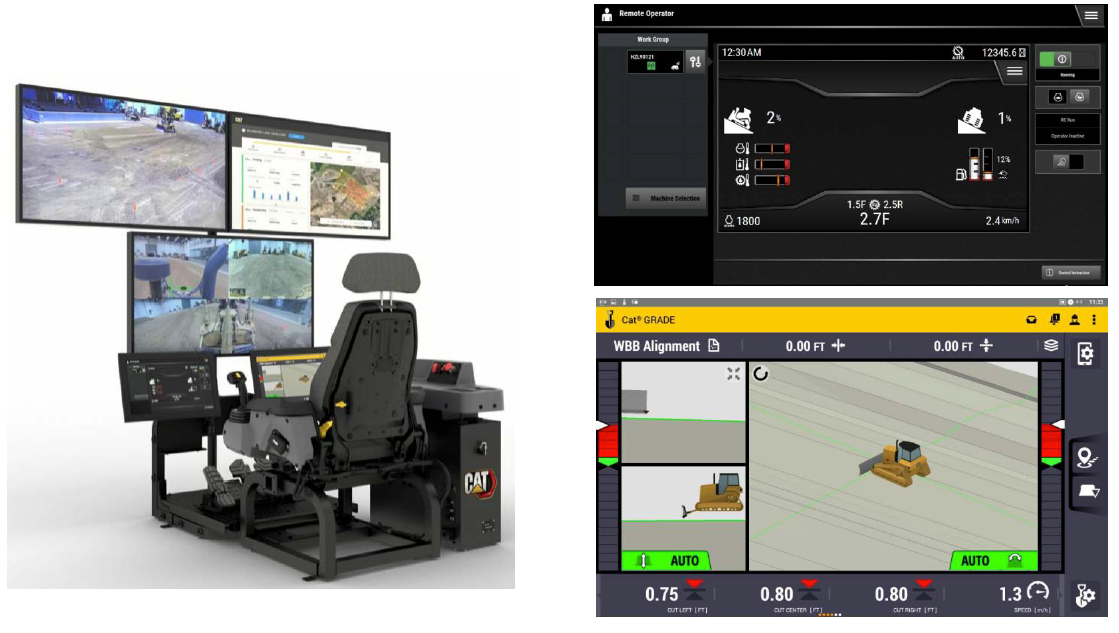

Enter the new Cat Command Station, which looks more like a virtual reality training station. But the machines the operators are controlling in the station are quite real.

The Cat Command Station is designed for what is referred to as non-line-of-sight operation. Operator and machine can be around the corner … or miles away.

Out of the cab

To be clear: this is not a solution for more typical in-and-out earthmoving applications.

So why would contractors want their operators operating a machine they aren’t in and in most cases can’t see?

The topmost answer is safety.

For example, Saiia Construction, Birmingham, Alabama, is using the Command Station to get operators out of ash pond removal sites. On these sites, ground that appears solid can quickly shift after rain and other factors.

Another early adopter is Associated Terminals, Convent, Louisiana, which uses Command Stations to operate wheel loaders and excavators in the barges it unloads.

Beyond seat feel

In developing the Command Station, Cat purposely decided not to use a simulated “seat feel” – or that comes-with-experience judgment of physical inputs such as vibration, rocking, tilt, etc.

While it would be natural to think that these inputs still needed to exist in a remote-control station – such as what’s on a virtual reality motion platform where the seat motion is integral to the overall experience – Cat says its research proved differently.

“We’ve looked at this for more than 10 years, and we found that an operator’s vision sense takes over,” says Alan Pumklin, product specialist with Cat’s Digital and Technology Group.

During the Command Station R&D stage, Cat gradually filtered out seat motion, and “overwhelmingly operators were able to overcome the fact that they didn’t have that vibration and feedback,” Pumklin says.

Eliminating a motion platform also allowed Cat to greatly simplify the Command Station and lower costs.

“Ultimately, the whole point of removing the operator is to remove him from that dangerous environment, and motion wasn’t required to perform remote-control operations,” Pumklin says. “The operators did not miss it.”

Also eliminated: the physical wear and tear that comes with constantly adjusting to machine motion.

Instead of seat feel, Command Station operators look for visual clues – such as pitch and roll on a dozer – that they would normally have gotten through the physical machine.

The machine is also miked. A microphone is placed on the cab, so operators hear machine sounds – including the series of honks warning bystanders that a machine is about to switch to remote control.

The microphone enables operators to hear such things as the final drives on a dozer and to stay aware of what’s happening on the machine.

“Most operators grasp the concept pretty quickly,” Pumklin says. “You’re not missing information; it’s just now mostly visual instead of physical.”

He offers this illustration: operators are instructed to put down a dozer blade and stop when the blade starts to lift the machine.

All operators will stop when instructed, Pumklin says, but not because they feel anything. It’s because they see the machine hood come up. The horizon changed.

Hot lunches

The inherent comforts of Command Station might help convince operators they don’t need to be in the actual machine.

Situated in a jobsite trailer or an office, operators may be able to wear regular street shoes and heat up lunch. They’re protected from the weather, and the bathroom is down the hall instead of parked in a field.

In a Cat video promoting its use of the Command Station, Saiia Construction also adds another benefit: it gives people the ability to operate a machine even if they have a physical condition that may keep them out of a cab.

“One of my guys has a medical issue that prevents him sometimes from climbing on the machine,” Clint Kennedy, Saiia superintendent, says in the video. “On the weeks that he can’t get into the machine, he can come into the Command Station and run his machine from here without any loss of production.”

Getting on and off machines is one of the top five causes of construction equipment-related injuries, Pumklin says. “Customers have clearly seen the benefits of being able to reduce that risk or eliminate it entirely.”

Another benefit is training: most cabs don’t have space for trainers. Working with the Command Station, however, gives trainers true over-the-shoulder instructional capabilities.

Operate three machine types from one station

Another big change with the Command Station from the normal operator experience: with a push of a button, you can switch from operating a wheel loader to a dozer or to an excavator. Three very different machines are operated by one set of controls. And each Command Station can have up to five machines in its workgroup, one at a time. Infinite number of machines can be moved in and out of the workgroup.

Since the controls of these three machines are quite different, how is this accomplished?

“When you switch between machines, it changes the mapping of the controls,” Pumklin says. The touchscreen display also changes, and the selected machine’s cameras are displayed on the station monitors.

Immediately after a machine change, the touchscreen display will show the joystick control instruction illustration of the new machine. “You can’t even start the machine without removing the instruction manual,” Pumklin says. (This feature can be disabled when operators get comfortable with switching between machines.)

Command Station controls Cat’s Command Station universal controls are used to operate three very different machines: excavators, wheel loaders and dozers.Equipment World

Cat’s Command Station universal controls are used to operate three very different machines: excavators, wheel loaders and dozers.Equipment World

Command Station controls most resemble those in an excavator although there are differences. The two joysticks are more squarish and there are three pedals instead of two. As with the physical machine, though, operators can change control patterns according to their preferences.

When operating a wheel loader, the controls convert to those of a joystick steer loader, and as opposed to the excavator, all three pedals are used.

When you switch to controlling a dozer, the left joystick is remapped to forward and reverse and left and right steering. The right joystick raises and lowers the blade, tilts it left and right, and angles it left or right. The pedals are reconfigured to a decelerator and a service brake.

“There is an adjustment [when you switch between machines], but it hasn’t been a huge issue because operators know they are in the station and not in that specific machine,” Pumklin says.

For example, Pumklin says, “we superimpose the pitch and roll of the chassis on the dozer touchscreen so you always know the pitch and roll.”

The starting up process of a machine is the same as on the physical machine, with the operator keying in settings on the touchscreen display, which can be positioned for comfort with an adjustable mounting arm.

And the operator receives all the warnings – such as low fuel – that he would if sitting in the cab. A Remote Shutdown Switch button on the Command Station quickly halts machine movement.

Visibility

Because of the camera positions on each remote-controlled machine, operators get visual information beyond what they can see in the actual cab, Pumklin says. From a single screen, operators can now see all the way around the machine, instead of having to turn their head.

In a dozer, for example, two cameras show the left and right blade tips. One camera is positioned over the cab, and another is on the back of the machine.

On a loader, the cameras give operators a look into the top of the truck they’re loading, now not an option from the in-cab seat.

If the operator stands up in the Command Station while the machine is in motion, a seat sensor activates the parking brake and hydraulic lock, and the machine goes into a low idle.

When operators resume their seat, they can then release the brake and lock, and the machine becomes operational again. Cat says operators will be able to shift their weight around on the seat without setting off the seat sensor.

How it works Cat Command Station communication path: Operating commands are sent directly from the operator in the Command Station to the machine’s electronics through a dedicated wireless radio. The machine electronic control modules (ECMs) receive the signal and respond to the command. Machine parameters and status are fed back to the station through its ECM, receiver and wireless radio.Caterpillar

Cat Command Station communication path: Operating commands are sent directly from the operator in the Command Station to the machine’s electronics through a dedicated wireless radio. The machine electronic control modules (ECMs) receive the signal and respond to the command. Machine parameters and status are fed back to the station through its ECM, receiver and wireless radio.Caterpillar

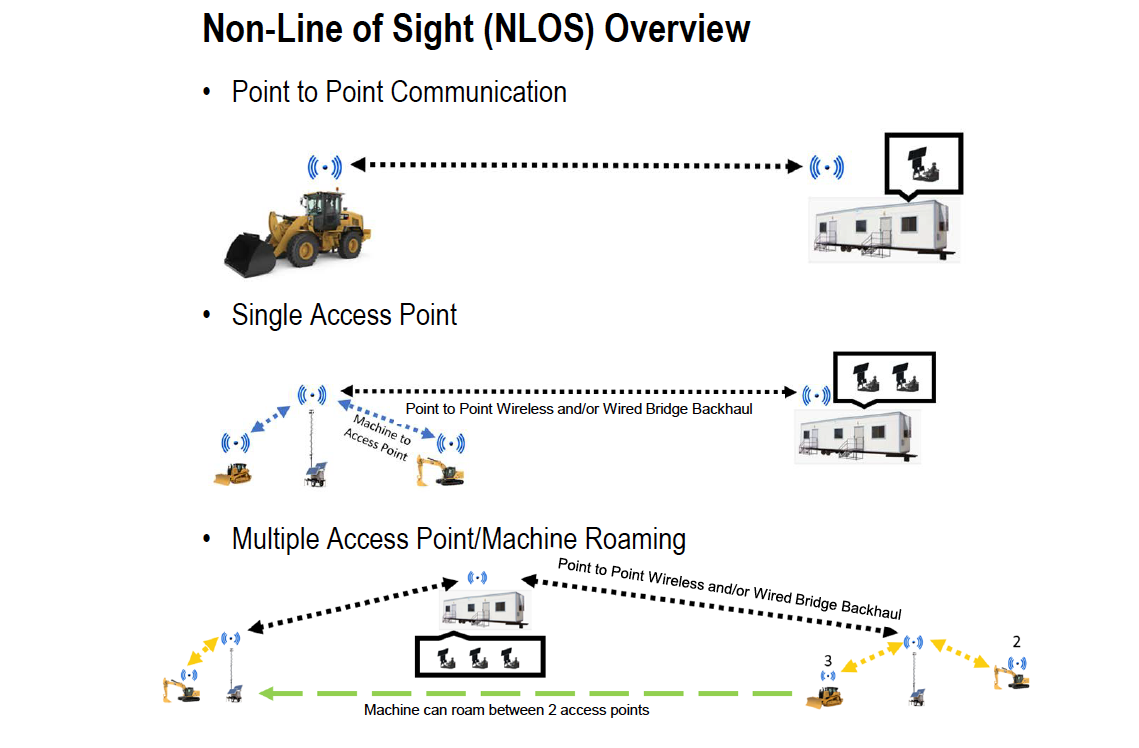

How a customer sets up a Command Station system will vary as much as the applications these machines are used in, Pumklin says, ranging from a single machine connection to several machines in a fleet.

A simple setup involves a point-to-point network. Depending on the machine, it will either come remote-control ready or it can be retrofitted. The station can be put into a mobile trailer onsite (or elsewhere), a radio signal is established between machine and the station, and the network system basics are in place.

Here’s a simplified look at how the Command Station remotely controls a machine:

Operating commands are sent directly from the operator in the Command Station to the machine’s electronics through a wireless radio. The machine electronic control modules (ECMs) receive the signal and respond to the command. Machine parameters and status are fed back to the station through the ECMs and wireless radio.

More complicated setups involve multiple machines connected to one access point. The system is also capable of multiple access point connections, which allow machines to move between multiple access points.

The hardware

“We’re not adding solenoids or cutting into the machine,” Pumklin says. “These machines are already designed to work with remote control.” In Cat’s 2021 annual product update, for example, D5 through D7 dozers come remote-control ready.

The technology is also scalable. Users can start with the installed machine componentry used to operate a machine with an over-the-shoulder, line-of-sight remote-control console. They can then add IP cameras and wireless radio if they decide to convert to a Command Station non-line-of-sight system.

What’s in the control station Positioned either in an office or a jobsite trailer, Cat Command Station operators are out of the elements and shielded from machine movement. Here, the displays for a D6 are shown.Caterpillar

Positioned either in an office or a jobsite trailer, Cat Command Station operators are out of the elements and shielded from machine movement. Here, the displays for a D6 are shown.Caterpillar

The station includes a touchscreen display for machine controls, an optional second touchscreen for additional functionality (such as Cat’s Grade with 3D), a remote-control ECM and a router.

The station screens are HDMI-connected TV monitors. Customers can buy them off the shelf at their local Best Buy and get them as large as they want and position them accordingly. Operators can also position how close they are to the monitors.

Since radio frequency transmitting device requirements change from country to country, Cat sets the network requirements for but does not provide transmitting devices.

The rest of the station – seat, base, controls and touchscreens – is included in an easy-to-assemble module that can be transported separately and put together on site, Pumklin says.

What’s on the machine

While remote-control ready machine rollouts are occurring throughout this year, let’s look at what a dealer-installed retrofit kit on a loader would contain:

- Four high-definition cameras inside and outside the cab, light-bar indicator lights, microphone, wireless radio and antenna installed on the roof.

- Electric-over-hydraulic steering system.

- A ground-access Command activation lever.

Also recommended: optional site cameras, which give an overview of the jobsite surrounding the machine.

On the jobsite, an optional remote A-Stop control is available for people working around non-line-of-sight remote-control Command machines. When activated, the handheld control stops all remote-controlled machines within its broadcast radius and each roof-mounted machine light turns red.

The remote-control mode lights on the roof-mounted electronics enclosure indicate when a machine is being operated remotely.

Blinking blue lights mean the machine is being controlled remotely and for any surrounding personnel to stay away. Solid blue indicates RC reserved mode; a 3-second honk followed by three honks will sound and the lights will start blinking before operation restarts.

Technicians working on a remote-control machine would first observe that it is in RC reserved mode. They would then turn the machine to manual by flipping a ground-level switch; this disables the remote-control connection. A green light displays on the roof-mounted light bank, and the machine can now be operated conventionally.

Going rogue?

Cat wants to allay concerns about a remotely controlled machine going “rogue.” It says the machine comes to a complete stop whenever there’s a break in communications.

“Our systems are designed to go into a safe state when an errors or issues occur,” Pumklin says. “It’s a low drama event; it’s not a big deal to get it started again.” The Command Station also has a large red stop button on its console.

Someone within 1,000 feet of a machine can also deploy the A Stop, which Pumklin describes as resembling a garage door remote.

Once used, only that transmitter can unlock it. “It’s like a lockout/tagout,” Pumklin says. In addition if a machine goes outside the network coverage work area, it will lose signal and stop.

Available now

The control station can be ordered on 926M, 930M and 938M wheel loaders has already started.

The Cat Command system on 320, 323, 326, 330, 336 and 340 excavators will debut this quarter. Next up will be the D5, D6 and D7 in the fourth quarter.

Cat intends for the vast majority of their product line to become Command compatible over time. As they come on board, different switches and rollers might be added to the controls, but they will likely retain their present overall configuration, according to Pumklin.

This does bring up the question: if three machines can be controlled by a set of common controls, will that transfer over into the actual machines?

While this could be possible, Pumklin says, customer and operator acceptance of such universal controls is another question.